Add to Cart

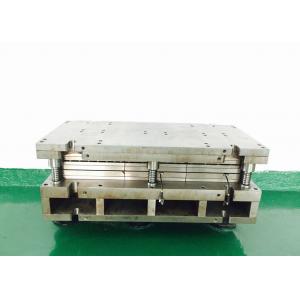

| Item | Customized deep drawing tool progressive stamp press die mold tool |

| Mold Material | SKD11, D2, SKH-9,SKH51, SKD61, Cr12Mov, Tungsten carbide etc. |

| Type | Progressive die |

| Press machine | Base on molds specification |

| SPM | 30-60 PCS pe minute in general, Max 600 pcs/Min |

| Mould Tolerance | 0.001-0.003mm by wire-cutting process |

| Life Time | Max 10 million times, normally 1-3 million times |

| Delivery time | 25-50 days on receipt of down payment |

| Trade Term | FOB Shenzhen, EXW, CIF etc. |

Company intruduction

1. ODM&OEM service are all welcomed

2. Practicable Software: Solidworks,Pro/Engineer,Auto CAD,PDF,JPG

3. Small orders accept

4. Reasonable and competitive price according to your drawings

Shenzhen Xinwangtai Precision Mould Products Co., Ltd. is an ISO 9001:2008 certified Manufacturer and Supplier of metal stamping tools, and stamping parts, Our main production scope is kinds of deep drawing stamping molds making and deep drawing parts manufacture.

With the support of hardworking and rich-experienced engineers, we are excellent at customizing the molds and parts as you required. Along with these, we also undertake design & development work of press tools, fixtures & gauges and re-engineering & prototype development.

We are a professional manufacturer which can provide you customized molds and stamping parts strictly according to your drawings or specific requirements. Pls send your drawings or samples and we will try our bset to meet your demands.

If you are interested in our products, please contact us without hesitaion! All inquiries will be replied within 24 hours.

Our company specializing in the production of mould and stamping, customed deep drawing parts are processing.

Our products are frequently exporting to Japan , Netherlands , France, USA , Singapore , Spain , Israel and other countries

Advantages

*Over 14 years working in this field with strict quality controlling system

*Sample testing report, CMM report, Raw material report can be provided

*Free for designing mould from professional engineer designer

*Sodick Slow-feeding wire-cutting machines six sets, precise process.

*Punctual delivery date.

*Direct manufacturer, cost and timing saving

*All process are made by our own factory, we can control all steps well to get high quality mold.

*Small order can be accepted.

FAQ

1. Q: Are you a factory or trading company?

A: We are a factory,There are 4,000 square meters of manufacturing plants and RD bases in our factory.

2. Q: What products do you supply?

A: we are specialized in stamping progressive die and stamping parts, deep drawing parts is our main range.

3. Q: Where is your factory located? How can I visit there?

A: Our factory is located in Shajing Baoan Shenzhen City, Guangdong Province, China,We warmly welcome all our clients, from home or abroad, to visit us!

4. Q: What is the material of your molds?

A: The material are DC53,SKD11,D2,SKH-9,SKH-51 ,ASP-23, Tungsten steel.

5. Q: What the press your fatory have ?

A: There are 30T,60T,110T,160T, 200T press machines in our factory.

6. Q: What about the equipment of your factory?

A: Our factory owns a full set of Machining equipment, include large CNC machning center,Sodic EDM machning,import EDM-HS,Radial drilling machines,Milling machines,Grinders,three-D inspection etc.

7. Q: How does your factory do regarding quality control?

A: Quality is priority. We always attach great importance to quality controlling from the very begining to the very end. All the mould, the QC measure with three-D measuring equipments regularly.

Quality Control:

1) Technicians self-check in production

2) Engineer spot check in production

3) QC inspects after mass production finished